The Basic Principles Of Sikorsky Approved Supplier List

Wiki Article

Rumored Buzz on Sikorsky Approved Supplier List

Table of ContentsSome Known Details About Sikorsky Approved Supplier List Sikorsky Approved Supplier List Fundamentals ExplainedSome Known Incorrect Statements About Sikorsky Approved Supplier List Getting The Sikorsky Approved Supplier List To WorkWhat Does Sikorsky Approved Supplier List Mean?Sikorsky Approved Supplier List Things To Know Before You Get This

KAMAN K-1200 K-Max synchropter In an alongside rotor configuration, 2 horizontal, counter-rotating rotors are placed side-by-side on a helicopter (or transverse rotorcraft). The anti-torque impact is provided by the opposing rotation of both primary rotors. The side-by-side configuration is one of the possible flight arrangements of a tilt-rotor airplane, when the rotors remain in the vertical setting to supply vertical lift.It is essential that parts are formed and ended up in a proper style. As a helicopter spare parts supper in the USA, Jones Steel Products is below to develop as well as finish helicopter parts in an exact and prompt fashion. Jones Metal Products has more than 95 years in the hydroforming industry, a process that we use for a range of parts in the aerospace and also defense sectors.

As a helicopter components vendor, Jones Metal Products consistently welcomes outside companies in for appropriate accreditations. These outside companies observe and also verify the different processes that we carry deal where we are making continuous advances in composite manufacturing of helicopter parts. ISO 9001:2015 without Design This accreditation ties to our top quality monitoring system.

Things about Sikorsky Approved Supplier List

When it happens a trusted as well as valued helicopter parts maker, making developments in composite manufacturing of helicopter parts comes with the area. The processes where we manufacture helicopter components are always being surpassed by our proficient team. Our group of designers, designers, and metalworkers have actually been innovating our solutions considering that the 1920s.

They can also help you to recreate older helicopter parts that originate from terminated runs all while keeping in line with our high standards of quality and regular production. Hydroforming, Rubber pad developing, Warmth treating, Stretch developing As a leading helicopter parts manufacturer, Jones Steel Products enjoys to work with customers in the aerospace, defense, and airplane markets.

Proud to be a lengthy time trusted helicopter components vendor, we are ready as well as waiting to listen to from you.

What Does Sikorsky Approved Supplier List Mean?

The autogiro he consequently designed bundled features of both the helicopter and the airplane, although it appeared like the latter more. The autogiro had a blades that operated something like a windmill. As soon as propelled by cabbing on the ground, the blades might create additional lift; nevertheless, the autogiro was powered largely by a standard plane engine.

To steer a helicopter, the pilot needs to readjust the pitch of the blades, which can be set three means. In the collective system, the pitch of all the blades connected to the blades is the same; in the cyclic system, the pitch of each blade is created to rise and fall as the blades revolves, as well as the 3rd system utilizes a combination of the first two - sikorsky approved supplier list.

Examine This Report on Sikorsky Approved Supplier List

A related issue takes place due to the fact that, as the helicopter progresses, the lift beneath the blades that get in the airstream first is high, but that below useful content the blades on the opposite side of the blades is low. The internet result of these problems is to undercut the helicopter. Usually, the means of making up for these unpredictable variants in lift as well as drag is to produce versatile blades linked to the blades by a hinge.

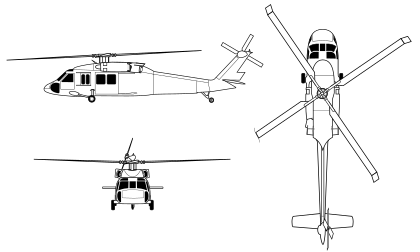

Torque, one more problem linked with the physics of a rotating wing, triggers the helicopter body (cabin) to revolve in the contrary instructions from the blades, specifically when the helicopter is moving at low rates or hovering. To offset this response, many helicopters make use of a tail rotor, an exposed blade or ducted fan mounted on completion of the tail boom usually seen on these craft.

He explored important source for even more than twenty years and also ultimately, in 1939, flew his first trip in a craft called the VS 300. Tethered to the ground with long ropes, his craft flew no more than 50 feet off the ground on its very first several trips. Also after that, there were problems: the craft flew up, down, and laterally, but not ahead.

How Sikorsky Approved Supplier List can Save You Time, Stress, and Money.

and asked to attempt one of their new primary frame office computers. By 1951, Parsons was explore having the computer's calculations in fact guide the maker device. His concepts were ultimately turned into the computer-numerical-control (CNC) maker device market that has changed contemporary manufacturing techniques. 1 Each individual tubular part is cut by a tube reducing machine that can be swiftly established to generate different, specific sizes and also specified set quantities.For aside from small bends, tubes are filled up with molten salt silicate that hardens and also eliminates kinking by triggering the tube to bend as a strong bar. The supposed water glass is then gotten rid of by placing thebent tube in boiling water, which melts the inner product. Tubes that has to be bent to match body shapes is fitted over a stretch developing maker, which extends the steel to an exactly contoured shape.

The straight from the source latter process involves injecting wax or an alloy with a reduced melting point right into a mold and mildew or pass away. When the theme has actually been formed, it is dipped in liquified metal as several times as needed to achieve the thickness wanted. When the component has dried, it is warmed to ensure that the wax or alloy will certainly thaw and can be poured out.

The Single Strategy To Use For Sikorsky Approved Supplier List

The plies are layers of oriented fibers, generally epoxy or polyimide, that have been fertilized with material. Complying with composed guidelines from the designers, employees develop very contoured skin panels by establishing specific plies on bond mold tools and sandwiching cores between extra plies as routed. 7 Finished layups, as the layers of prepreg affixed to the mold and mildew are called, are after that transferred to an autoclave for healing. sikorsky approved supplier list.Report this wiki page